Long Glass Fiber Reinforcement

Durability and Fatigue Resistance for Demanding Applications

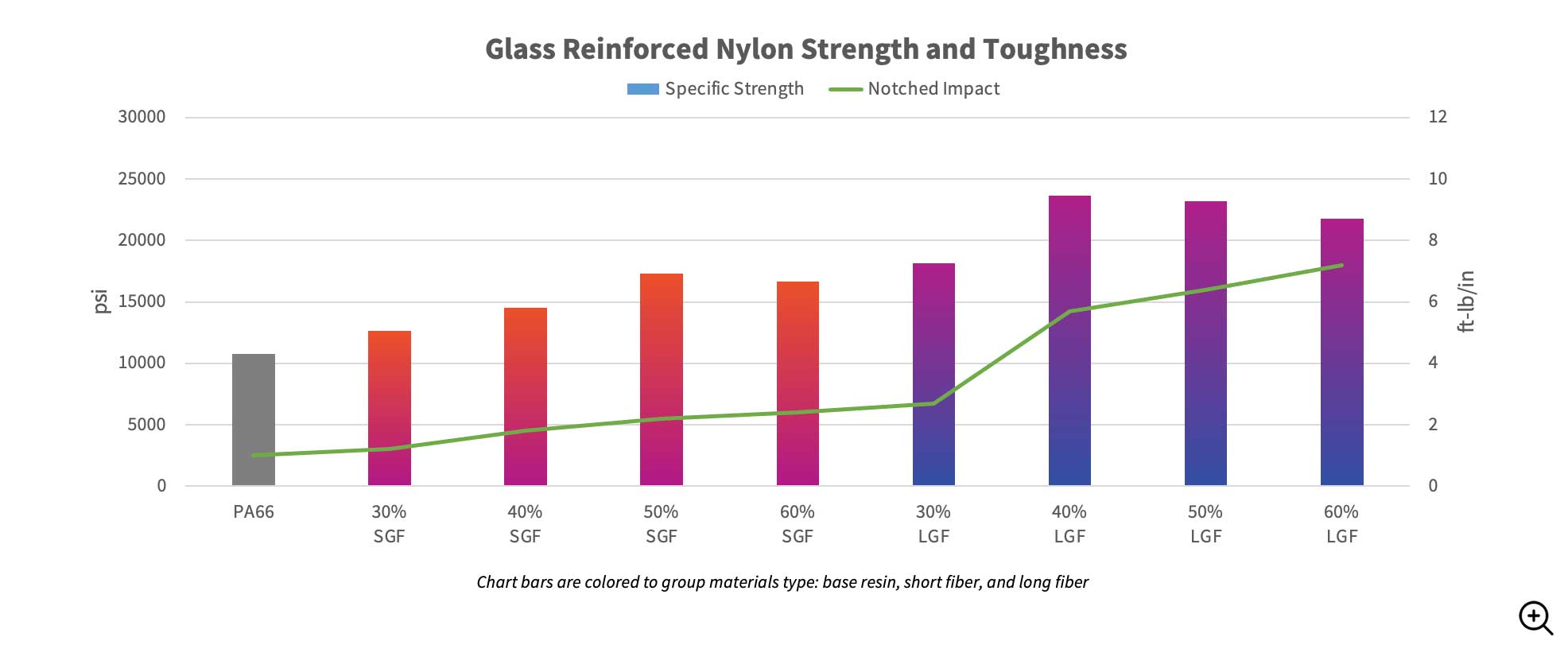

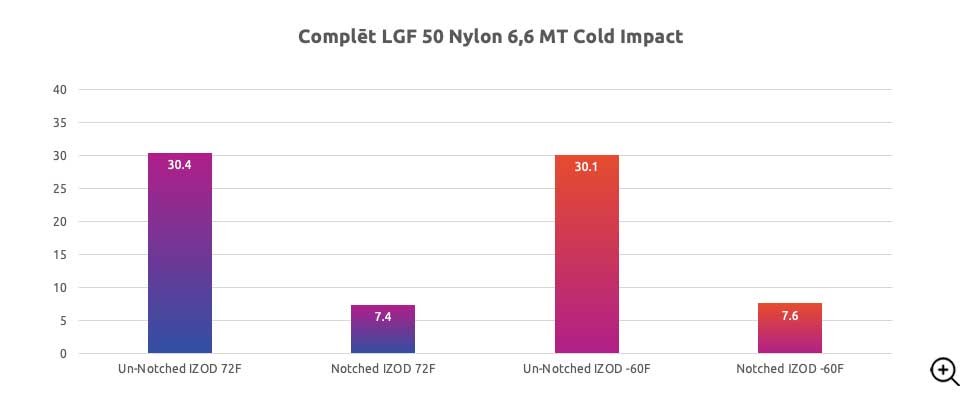

Reinforcing a thermoplastic with long glass fiber is a cost-effective way to boost mechanical properties of unreinforced resin systems and, even, short fiber solutions. It offers a noticeable improvement in stiffness and strength properties, but, more impressively, in impact strength. During processing these longer fibers intertwine and align to form an internal fiber skeleton that strengthens the polymer to help carry and dissipate stress forces – greatly increasing strength and impact resistance. This toughness is retained in demanding environments, such as cold temperatures (-60°F/-51°C).

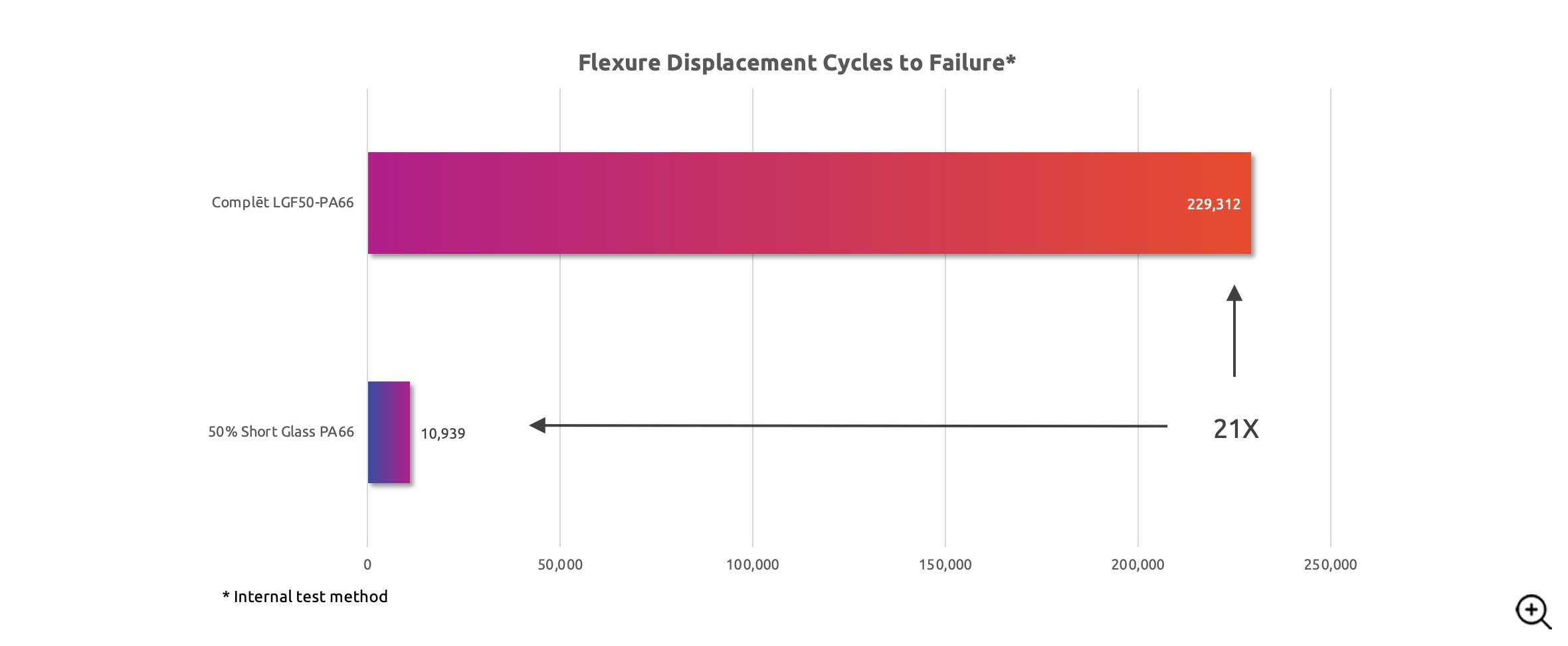

Long glass fiber composites start as continuous filaments of fiber, which we melt-impregnate with thermoplastic polymer in our pultrusion process to create a high performance bond. These unidirectional fiber-reinforced strands are then cut into 1/2 inch (12 mm) composite pellets for convenient processing into net shapes via injection molding. Higher aspect ratio fiber reinforcement through the full length of our pellets results in more robust properties than short/chopped glass fiber filled compounds. This also includes a significant jump in cyclical fatigue endurance and creep.

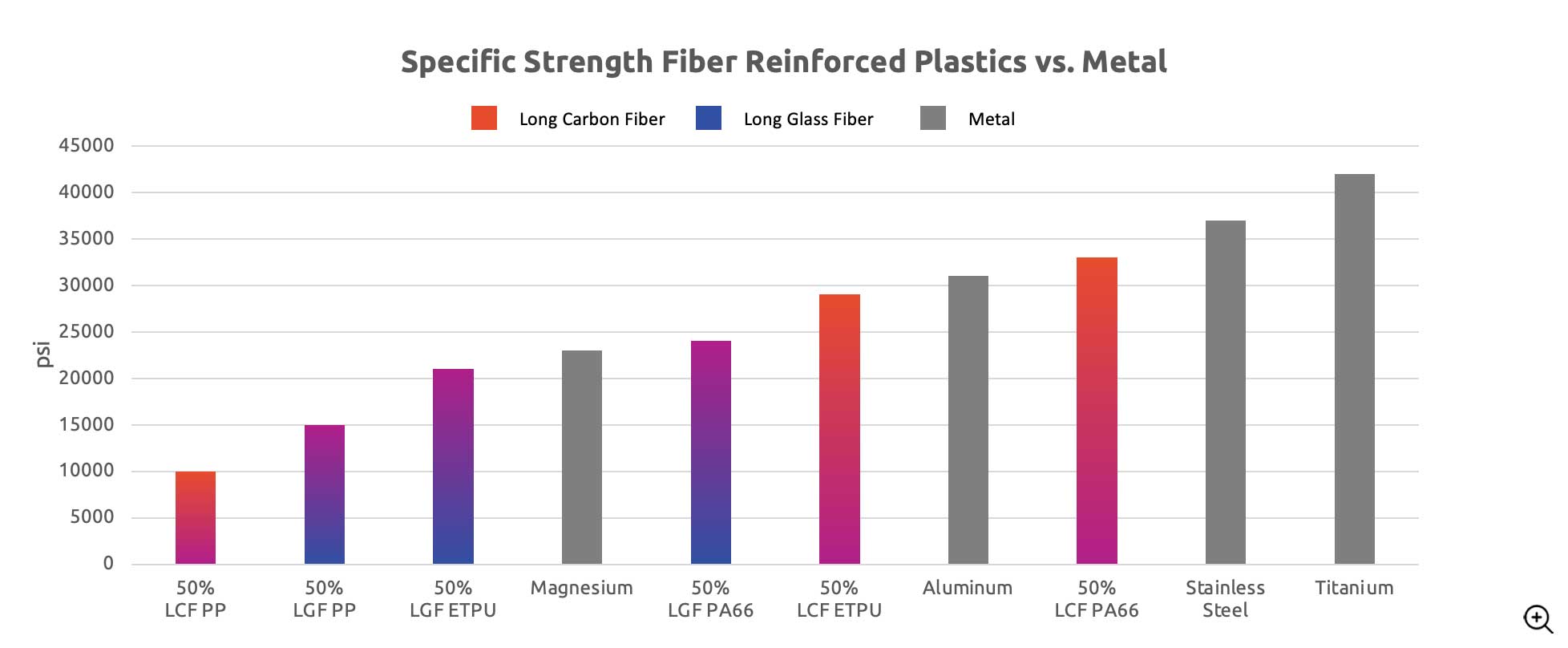

Long glass fiber is a strong yet ductile fiber reinforcement solution that is commonly used in metal replacement applications due to the high strength properties, lower specific gravity and attractiveness of the injection molding processing method. In conjunction with the advantages of organic design possibilities from the injection molding forming process, it is common to see a 40-50% weight reduction in applications when switching from metal incumbents (aluminum, magnesium). Part consolidation is also an area of benefit as well – eliminating the weight of fasteners and minimizing the risk of secondary assembly steps.

Our long glass fiber reinforced products range from 20-70% fiber content (by weight) across a variety of resin systems ranging from polypropylene to higher performance engineering polymers such as PEEK. Additive technologies such as custom color, lubrication and UV performance enhancement are also available to customize your solution.

Impact

- Strong yet ductile fiber option

- Exceptional toughness retained at low and elevated temperatures

- High fatigue and creep endurance

- Mechanical property retention at low and elevated temperatures

- Colorable for product branding or quick identification

- Go-to material for metal replacement with favorable economics

- Greater properties than short fiber/chopped glass fiber filled compounds

| Technical Property | Test Method | LGF30-PA66 | LGF40-PA66 | LGF50-PA66 |

|---|---|---|---|---|

| Specific Gravity | ASTM D792 | 1.37 | 1.45 | 1.59 |

| Tensile Strength | ASTM D638 | 25,550 psi | 30,000 psi | 33,500 psi |

| Tensile Modulus | ASTM D638 | 1,400,000 psi | 1,800,000 psi | 2,300,000 psi |

| Flexural Strength | ASTM D790 | 38,300 psi | 42,900 psi | 51,300 psi |

| Flexural Modulus | ASTM D790 | 1,270,000 psi | 1,720,000 psi | 2,300,000 psi |

| Notched Izod Impact | ASTM D256 | 2.4ft-lb/in | 3.7 ft-lb/in | 4.6ft-lb/in |

| Unnotched Izod Impact | ASTM D4812 | 13.0ft-lb/in | 17.5 ft-lb/in | 22 ft-lb/in |

| NAME | CATEGORY | DESCRIPTION | |

|---|---|---|---|

| Seat Pan for Off-Road Recreational Vehicle | Case Study (Snapshot) | Complēt™ long glass fiber reinforced nylon composite consolidated multiple metal parts to streamline manufacturing and assembly of an ATV seat pan | View |

| Step Linkage Automotive Aftermarket Part | Case Study (Snapshot) | Complēt™ LGF, moisture-resistant grade delivers improved performance and cost savings for aftermarket parts manufacturer | View |