Long Hybrid (Carbon + Glass) Reinforcement

Customized Performance Leveraging the Toughness of Glass Fiber and Strength of Carbon Fiber

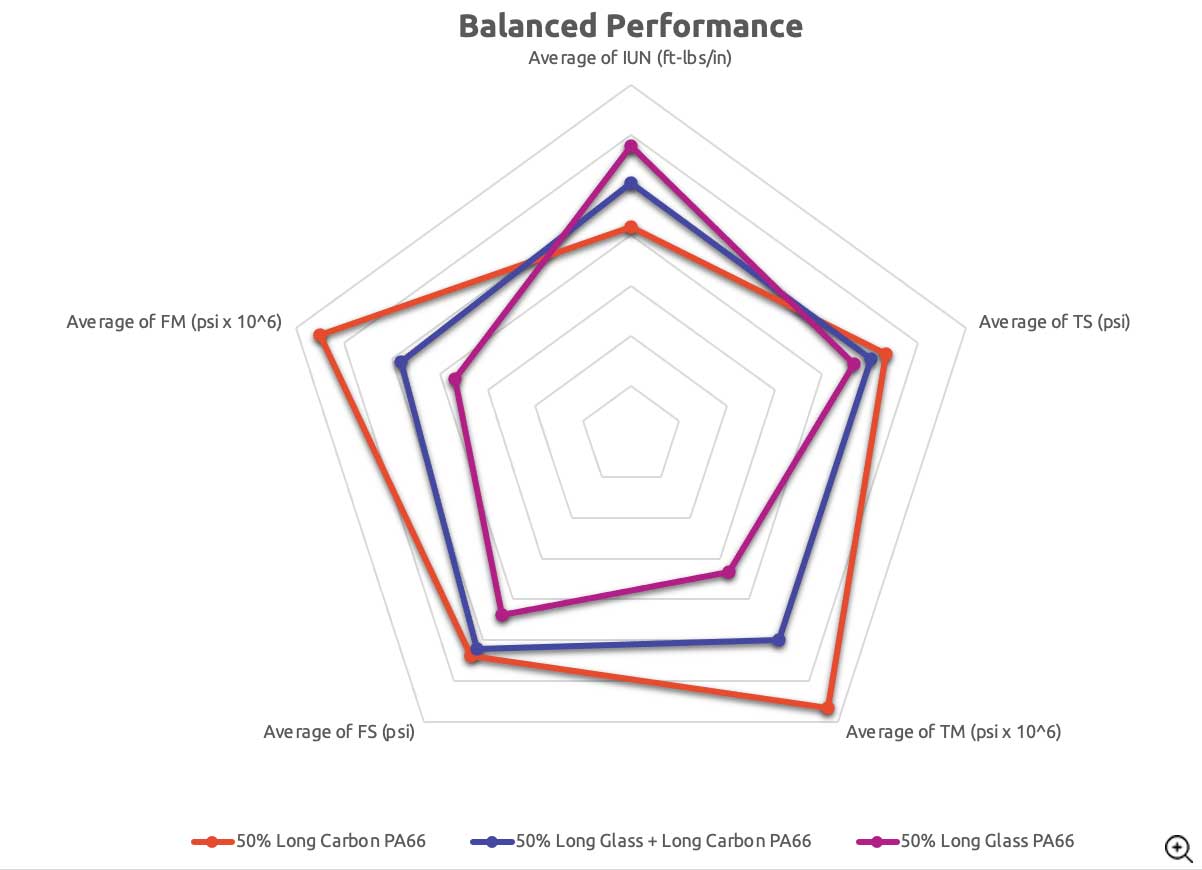

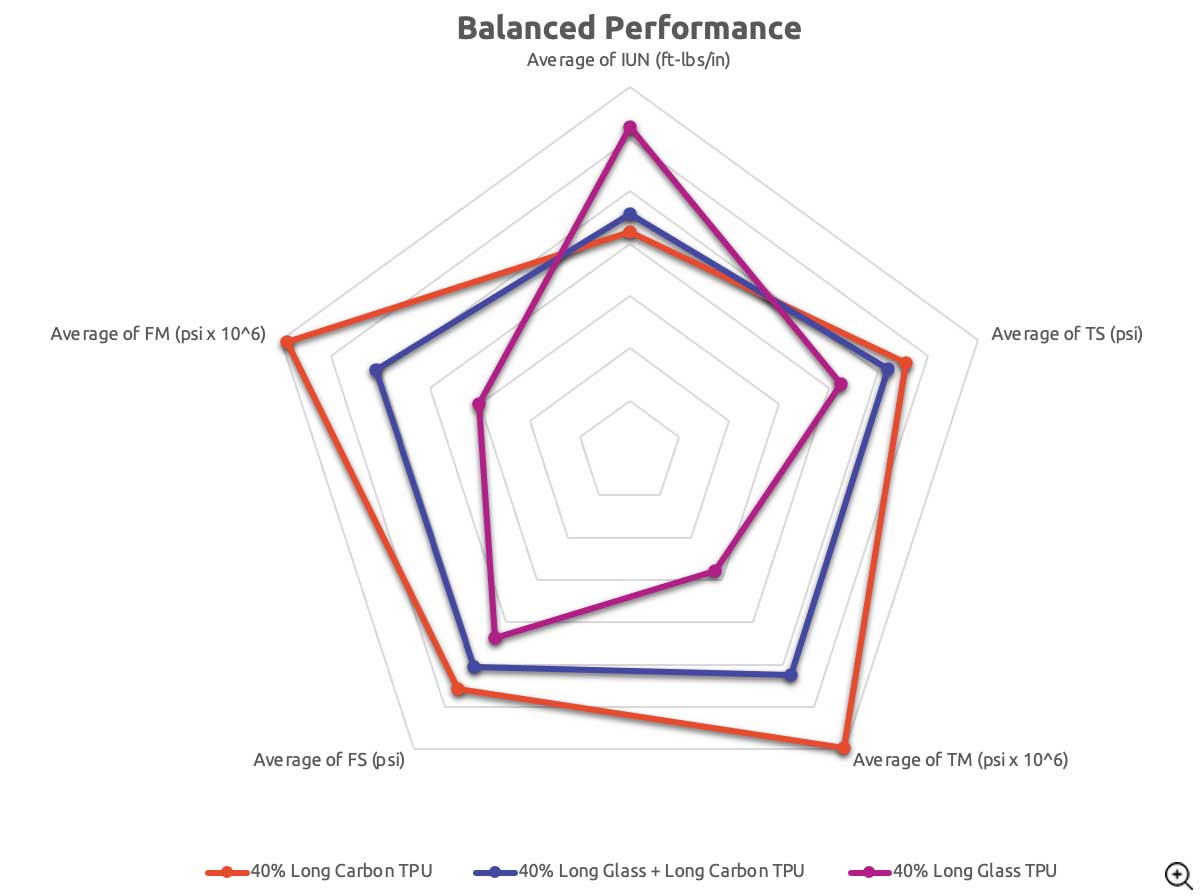

These are single-pellet solutions that blend a customized ratio of reinforcing glass and carbon fibers to help you achieve your performance requirements. Depending on the ratio of long glass to long carbon reinforcement selected, you are able to blend the best of both worlds – long glass fiber's toughness and economical cost with long carbon fiber's robust strength, stiffness and low density.

The long glass fiber reinforcement within the hybrid solutions offers a significant boost in toughness to the formulation, protecting your application from impact failure. You are still able to gain the strength of carbon fiber, but are also able to supplement a portion of the formulation with more economically priced glass fiber.

Long carbon fiber reinforcement within these solutions brings robust strength and stiffness properties. When selecting a hybrid solution there is also the added benefit of being able to promote the use of carbon fiber within your product – something that consumers are already well-versed with and associate with innovative and high-performance products.

Hybrid materials range from 20-50% total long glass + long carbon fiber content (by weight) reinforcing a variety of resin systems including polyamides, rigid thermoplastic polyurethanes and polypropylene. Additive technologies such as additional UV performance enhancement are also available to customize your solution.

Impact

- Carbon-to-glass fiber ratios customizable to balance performance and cost

- High stiffness and strength of carbon fiber at a more palatable price

- Excellent toughness and fatigue resistance of glass fiber

- Enable metal-to-composite conversions

- Unified pellet simplifies processing with uniform dispersion

| Technical Property | Test Method | LCG30-PA66 | LCG40-PA66 | LCG50-PA66 |

|---|---|---|---|---|

| % of Long Glass | 15% | 20% | 25% | |

| % of Long Carbon | 15% | 20% | 25% | |

| Specific Gravity | ASTM D792 | 1.33 | 1.40 | 1.44 |

| Tensile Strength | ASTM D638 | 38,500 psi | 42,500 psi | 44,500 psi |

| Tensile Modulus | ASTM D638 | 2,500,000 psi | 3,500,000 psi | 4,000,000 psi |

| Flexural Strength | ASTM D790 | 56,000 psi | 58,000 psi | 62,500 psi |

| Flexural Modulus | ASTM D790 | 2,500,000 psi | 3,000,000 psi | 3,500,000 psi |

| Notched Izod Impact | ASTM D256 | 3.3 ft-lb/in | 4.2 ft-lb/in | 4.6 ft-lb/in |

| Unnotched Izod Impact | ASTM D4812 | 16.0 ft-lb/in | 18.0 ft-lb/in | 19 ft-lb/in |

| NAME | CATEGORY | DESCRIPTION | |

|---|---|---|---|

| Personal Watercraft OEM Steering Column | Case Study (Snapshot) | Complēt Hybrid Moisture Resistant Composite provided part consolidation, design consultation, and robust FEA support | View |