Long Carbon Fiber Reinforcement

Low Density with High Stiffness and Strength Ideal for Replacing Metals

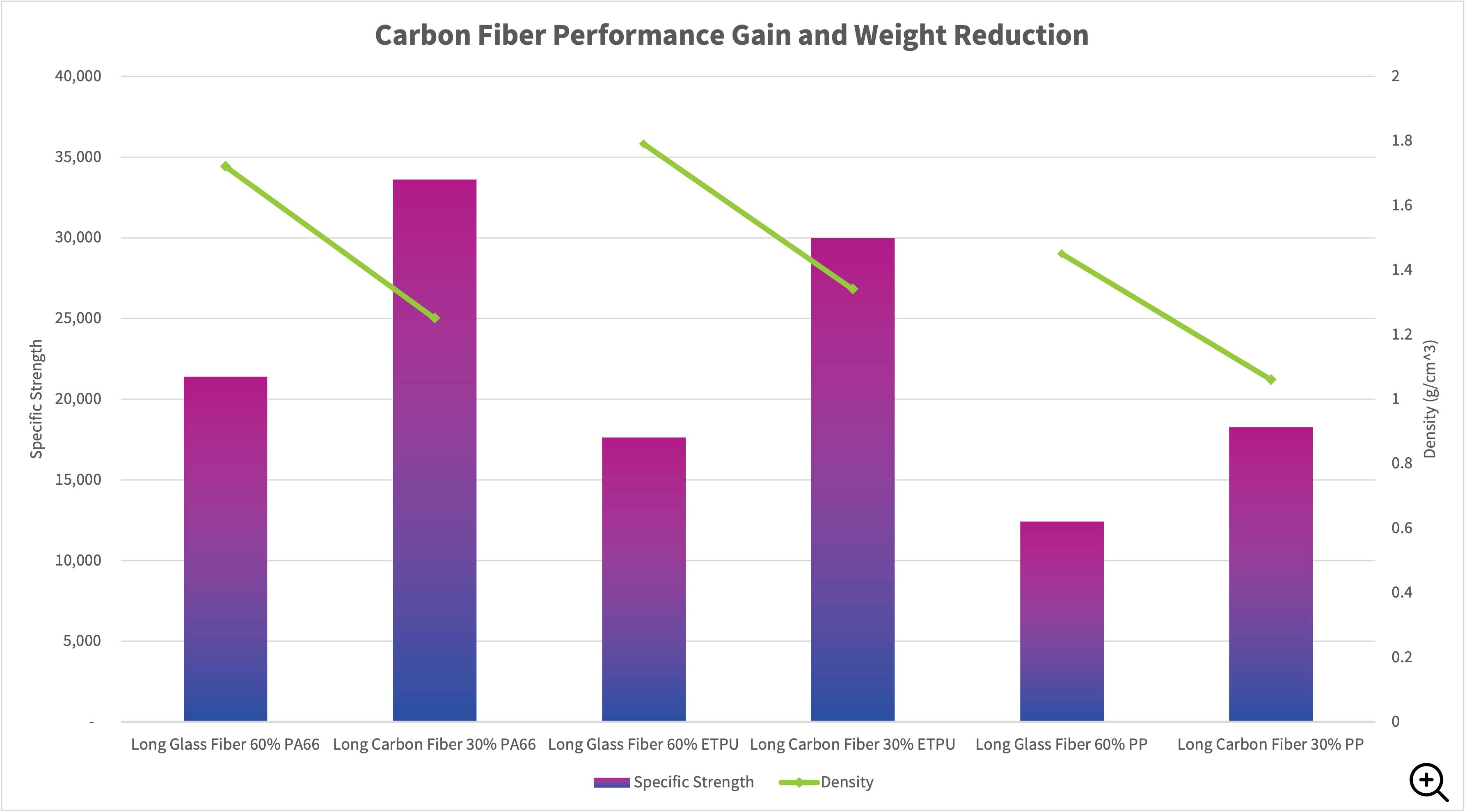

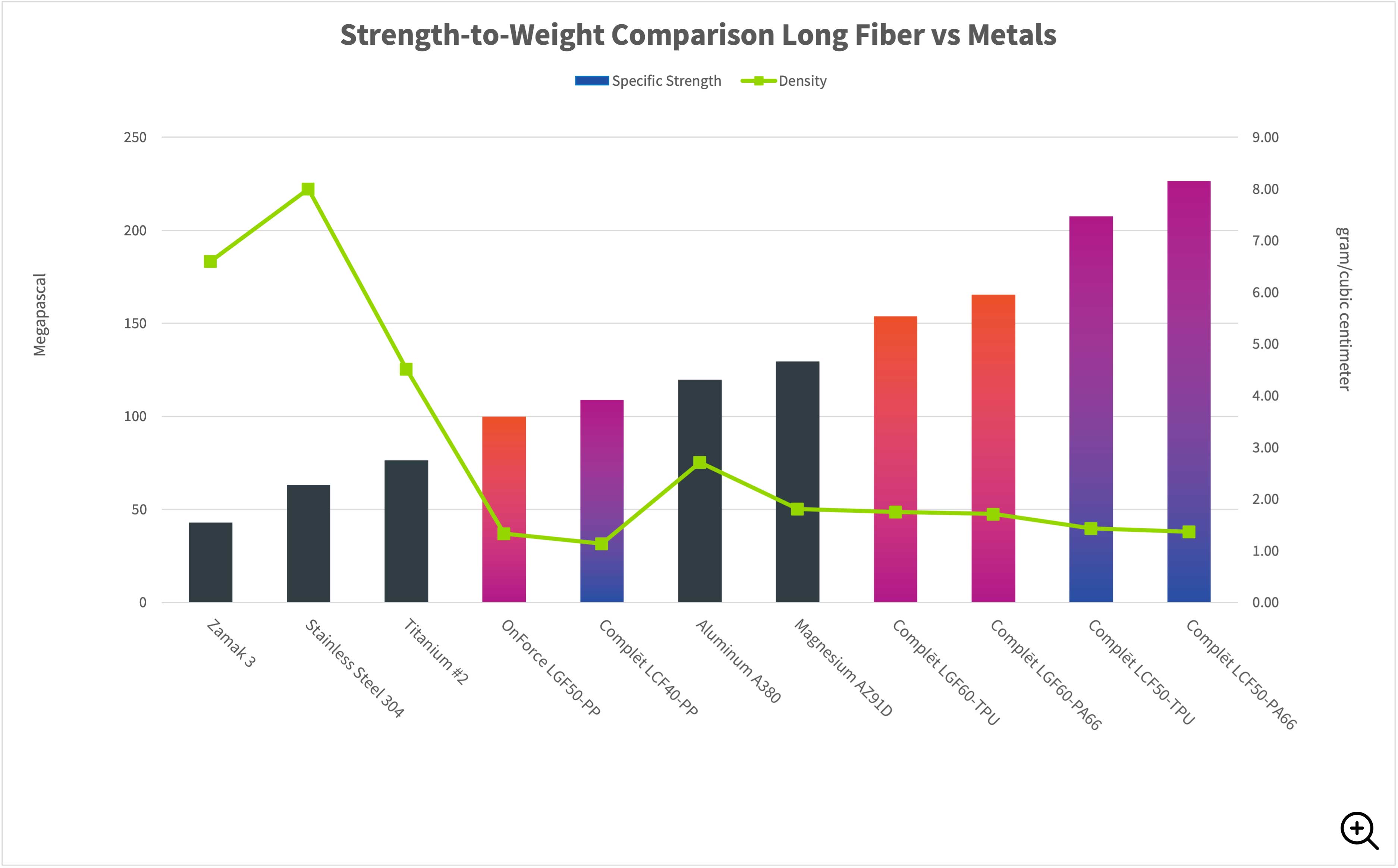

Lightweighting has become a buzzword for many industries, whether driven by the need to reduce energy consumption or the rise of device portability. Engineers looking to replace metals often face the dilemma of having to choose materials that potentially compromise performance in order to achieve mass reduction goals. However, our long carbon fiber-reinforced thermoplastic solutions are a perfect alternative due to their low specific gravity and robust performance.

In addition to being lightweight, high stiffness is also a key contributor to the success of long carbon fiber-reinforced thermoplastics. With a substantial boost in modulus, these compounds have yet another reason to compete with metals. Increased stiffness improves load-carrying ability and allows for designing with thinner wall sections, ultimately further decreasing material use and application weight.

Long carbon fiber composites are also utilized for their conductive nature – for instance, to be able to powder coat final aesthetic details. These products are also often leveraged to connect with consumers seeking a "high-tech" product due to the familiarity of carbon fiber strength in the market.

Overall, the superior mechanical properties of long carbon fiber reinforced composites make them an ideal substitute for metals. Combined with the design and manufacturing advantages of injection molding, long carbon fiber composites simplify the re-imagination of components and devices that have demanding performance requirements.

Our long carbon fiber products are sold under the Complēt tradename and range from 20-50% fiber reinforcement content (by weight). These fibers reinforce a wide array of resin systems ranging from polyamides to higher-performance engineering polymers such as PEEK. Additive technologies such as UV performance enhancement or impact modification are also available to tailor a solution for your specific need.

Impact

- High strength-to-weight ratio

- Superb load carrying ability

- Exceptional long-term creep resistance

- Cyclical fatigue endurance

- Resistant to deformation and crack propagation

- Outstanding dimensional stability

- Performance maintained at low and elevated temperatures

- Low coefficient of thermal expansion

- Dampen vibration and sound

- Incorporate multifunctional capabilities

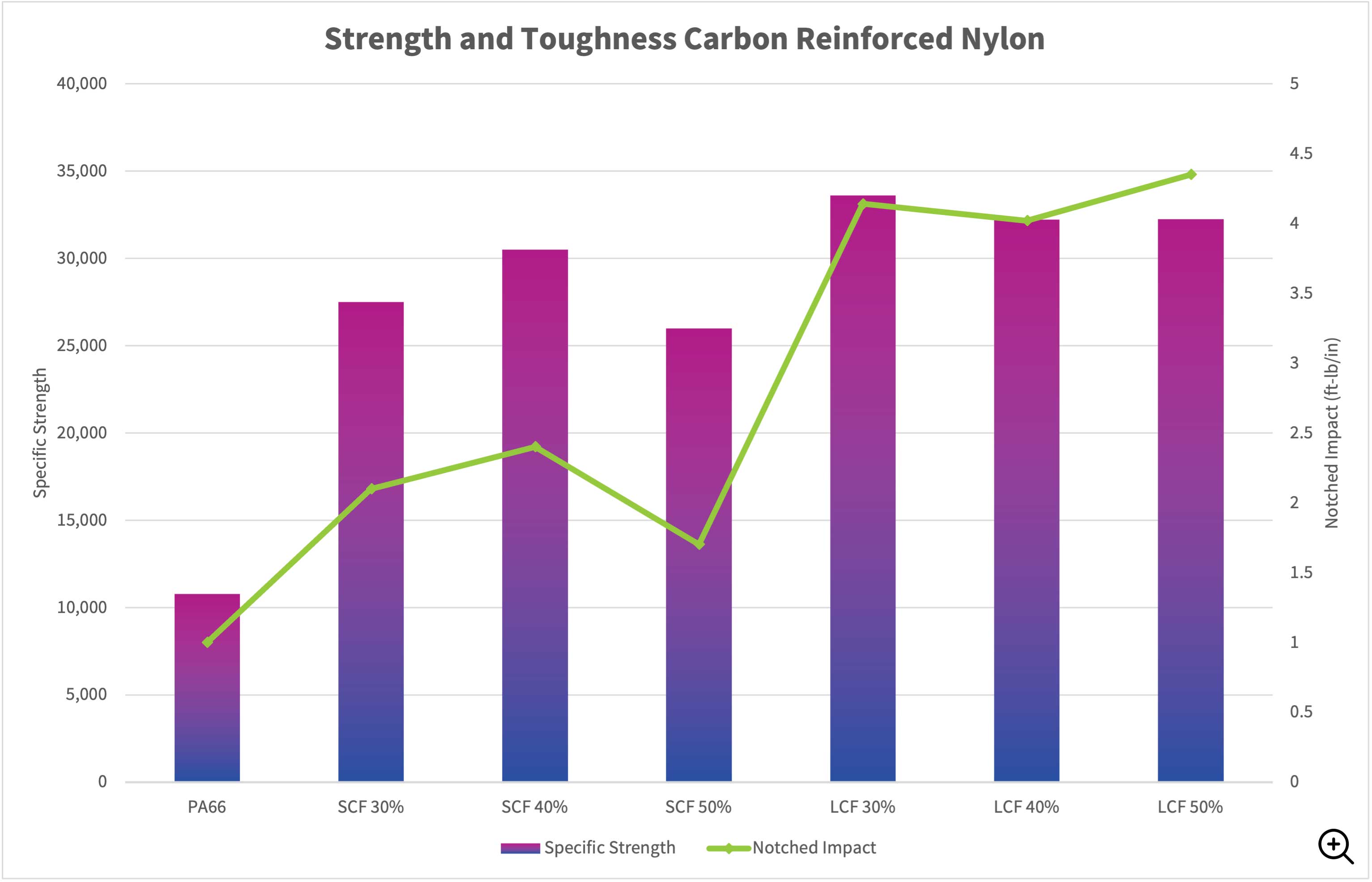

There is a continual increase in specific strength from short carbon fiber (SCF) reinforcement to long fiber reinforcement, and, further, as you increase fiber content loading. Notably, however, there is a large jump in impact strength with long carbon fiber reinforced products when compared to short fiber reinforced products.

| Technical Property | Test Method | LCF30-PA66 | LCF40-PA66 | LCF50-PA66 |

|---|---|---|---|---|

| Specific Gravity | ASTM D792 | 1.29 | 1.35 | 1.41 |

| Tensile Strength | ASTM D638 | 42,600 psi | 45,000 psi | 48,000 psi |

| Tensile Modulus | ASTM D638 | 3,600,000 psi | 4,500,000 psi | 5,800,000 psi |

| Flexural Strength | ASTM D790 | 56,000 psi | 65,000 psi | 70,000 psi |

| Flexural Modulus | ASTM D790 | 2,750,000 psi | 3,900,000 psi | 4,350,000 psi |

| Notched Izod Impact | ASTM D256 | 2.7 ft-lb/in | 3.2 ft-lb/in | 4.3 ft-lb/in |

| Unnotched Izod Impact | ASTM D4812 | 15.5 ft-lb/in | 16.2 ft-lb/in | 17.6 ft-lb/in |