Advanced Technologies and Sustainable Material Innovations from Avient Debut at Chinaplas 2024

April 23, 2024

Read More

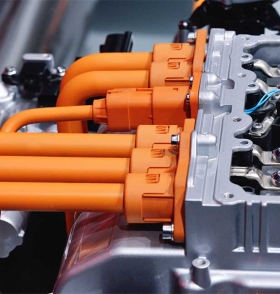

Avient Introduces Durable Orange Nylon Colorants for High Voltage Electrical Vehicle (EV) Connectors

Avient Introduces durable orange nylon colorants for High Voltage E...

Read More

Avient Pioneers New PTFE-Free LubriOne™ Internally Lubricated Formulations at Chinaplas 2024

Avient Corporation has expanded its LubriOne™ portfolio to includ...

Read More

ABRE Sustainability Forum to Include Highlights from Avient’s Sustainable Color and Additives Solutions

The Avient Color and Additives team for LATAM will showcase sustain...

Read MorePress Resources

Investor News

Apr 03, 2024

Avient To Hold First Quarter 2024 Conference Call... More

Feb 14, 2024

Avient Announces Fourth Quarter and Full Year 2023 Results... More

Feb 12, 2024

Avient Announces Quarterly Dividend... More

NEWS RELEASES

NEWS RELEASES

More NewsInvestor Events

May 07, 2024

Q1 Avient Corporation Earnings Conference Call More

Feb 14, 2024Q4 Avient Corporation Earnings Conference Call More

Nov 02, 2023Q3 Avient Corporation Earnings Conference Call More

More Events