An Extension of your Product Development Team

You’re not alone with our composite expertise on your team. Apply long fiber technology to cultivate marketplace innovation and produce enhanced products to grow your business.

As a material science company, PlastiComp focuses on bringing your product vision to life. We apply the technology and performance benefits of long fiber reinforced thermoplastic composites to make your products better – giving you an unbeatable marketplace advantage.

PlastiComp's Application Development Center is an impactful offering of technical resources to help drive that success with your program. Located at our Winona, Minnesota facility, the center encompasses skilled technicians, designers and engineers, all educated specifically in long fiber technology and ready to help.

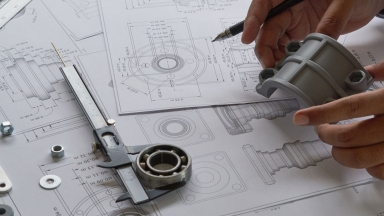

Design Support

We have a significant team of support resources ready to help you perfect your application. As both the technical formulator and manufacturer of the material solutions, we help with material validation to ensure that the best resin system, fiber selection and additive technologies are customized to meet your needs.

We also provide a variety of support with 3D modeling and simulation, working commonly with SolidWorks, Digimat, MoldFlow and Abaqus, to further promote confidence in our specialty materials. Further, our team can assist with part design optimization (including runner and gating setup) for the long fiber technology and can also review your tooling to ensure LFT molding optimization. Think of us as a direct extension of your engineering team.

In-House Prototyping Support

Our 55,000 square foot Application Development Center is most often leveraged for new program prototyping and R&D trials. We complete initial runs, tooling review and optimize suggested processing settings that can be communicated to your long term processer of choice. We also study fiber retention of these first shots and ensure that the material formulation selection is optimal.

We have press sizes ranging from 50 to 550 ton and are proud of our agility for in-house formulation modification, should it be needed. We also have the capability to do tolerance/quality reviews on your initial parts and can complete pyrolysis studies quickly to study fiber retention and performance. See your molded application from the inside out to gain confidence and visually see the strength of our composites.

Successfully using composites goes beyond simply swapping one material for another. Our product development engineers use an integrated approach taking into account component and tooling design, composite material performance, as well as manufacturing process to maximize material change benefits and quicken your time to market. Your success is our success which is why we are happy to showcase our Application Development center capabilities.

How We Can Help

Application Development

Application Development Center Technical Bulletin

Consider our technical experts to be an extension of your design and engineering teams. Learn what capabilities are available.

Learn More

Services

Specialty Engineered Materials Services

Simplify your development process. Leverage support for application understanding, material selection, application development, computer-aided engineering and onsite technical support.

Learn more

Design

Avient Design

Avient Design is a group of highly experienced industrial designers and project engineers. Our unbiased approach and unique combination of design, polymer science and manufacturing expertise help you bring amazing new products to market fast.

Learn more